The surface finish of turning depends on, among other things, the design of the cutting insert, the cutting and feeding speed, and built-up edge and vibration.

Turning operations are usually divided into coarse and fine turning, where the purpose of coarse turning is maximum cutting speed, while the fine turning performs the final machining to achieve the desired surface finish and dimensional tolerance.

In optimum conditions, the original dimension of the workpiece is so close to the final shape, also called near-net shape, that only fine turning is required to complete the detail.

From the tool's nose radius and feed speed, theoretical surface roughness can be calculated. However, vibrations in the tool or machine, tool wear, built-up edges and chip types can affect the final surface finish.

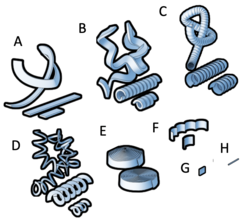

Chip Types

Surface roughness