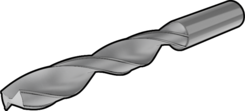

The twist drill is the most common tool used for creating a hole.

By rotation and pressure, the drill bit cuts the workpiece while the helical grooves help to pull the chips out of the hole.

It is usually made of high speed steel or cemented carbide.

Holes drilled with Standard twist drills having two cutting edges provide a high cutting speed. However, the back of the holes will be slightly conical, which may need to be addressed by reaming to achieve the desired tolerances.

In some cases, a process called intermittent drill can be good enough to achieve the desired results without the need for any subsequent operations.

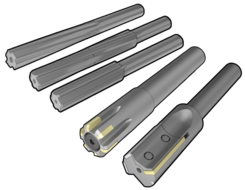

Intermittent drill

Intermittent drilling has two margins that allow the drill to get better SUPPORT AGAINST the drilled hole walls.

Reaming